The vibrating polishing machine produced by our company is designed for the grinding and polishing of automobile wheels. the abrasive movement track is more varied, and the polishing is more thorough and more efficient, using three vibration motors as the vibration source.It can also be used to polish larger hardware.

Polishing media can be divided into four types: Coarse media, Middle media, fine media and super fine media. Coarse media mainly polish burr and make work piece flat. The middle polish is to further process the work piece delicately whose burr was coarse polished. The fine polish is to make the work piece looks bright. The super fine polish is to polish mirror brightness. Coarse polish and middle polish should run with polishing media, to increase the cutting power of polishing media, also to avoid impact to work piece. Super fine polish must run with special brightness liquid and cleaning liquid.

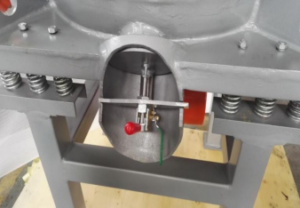

After The hub is fixed on the spindle then fill it with abrasive and polishing agent. Two vibrators installed with a certain Angle will drive the machine with abrasive and polishing agent to do the three-dimensional reciprocating motion, the abrasive will cause the collision with the hub, extrusion, scribing and other effects, the abrasive will always in the free state to achieve the effect of the polishing of the hub. at the same time the polishing agent will ensure the bright appearance of the hub.

1.simple structure,easy operation

2.different models for large and small wheels

3.Strong body, our engineer has redesigned the frame, use thicker and stronger material

4.Customize the voltage according to your needs.