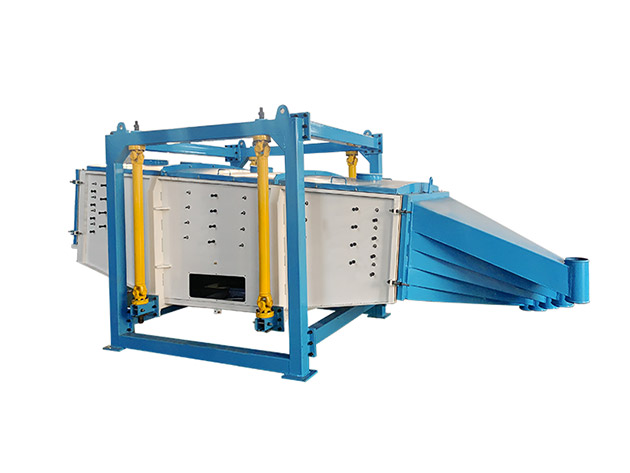

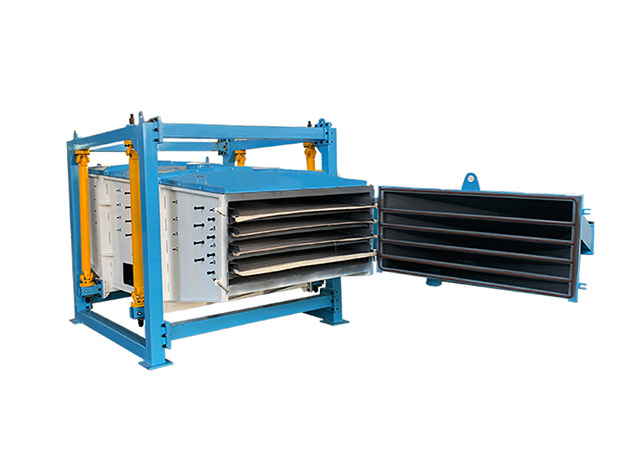

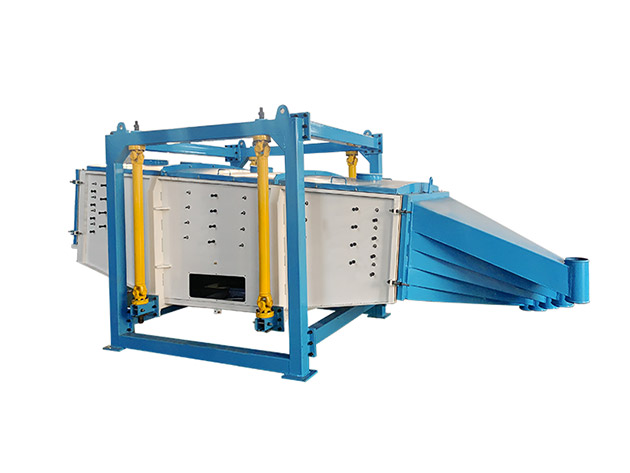

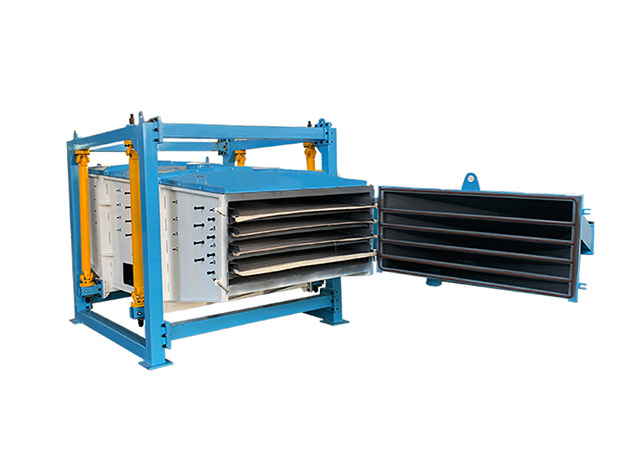

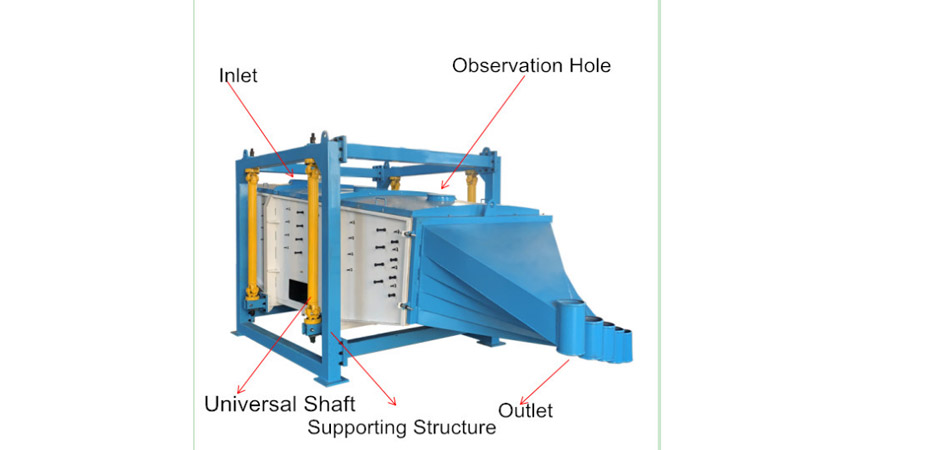

Gyratory sifter is one kind of high efficiency and large capacity sieving equipment. Users can realize high-output sieving needs of different materials by simply increasing or decreasing the spindle speed and the excitation force of machines.Gyratory sifter adopts a fully enclosed structure, which is easy to install and control. The general design is 3 ~ 5 layers, and it can grade 4 ~ 6 sizes of materials in the same time. Users can install the number of screen layers as required.

| Model | DZFY-1230 | DZFY-1236 | DZFY-1536 | DZFY-1836 | DZFY-2036 |

| Mesh size(mm) | 1200×3000 | 1200×3600 | 1500×3600 | 1800×3600 | 2000×3600 |

| Inclination | 5° | ||||

| Mesh | 6mm – 0.075mm(200# mesh) | ||||

| Layer(s) | 1-9 | ||||

| Power(kw) | 4 | 4 | 5.5 | 7.5 | 7.5 |

Gyratory Sifter is widely used in metallurgy, abrasive, non-ferrous metals, chemical, food, and other industries, especially for screening heavy alkali, sand,silica sand,salt, resin, fertilizer, urea, feed, reduced iron powder, zirconium oxide,ceramic, barite and etc.

Q: How long for the High output wollastonite powder Square Swing Screen Gyratory Sifter?

A: 7-20 working days.

Q: How long for warranty time?

A: 12 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation.

Q: About quality

A: Welcome to our factory and check the quality of product.We will send you the video and pictures before shipment after you order.