Vacuum conveyors utilize a pressure differential to cause material to move from one end to the next.

The vacuum feeder is the most advanced, perfect vacuum conveying equipment of powder material, granular material, powder-granular mixture. It can automatically transport a variety of material to mixing machine, packing machine, injection molding machine, grinder, etc…

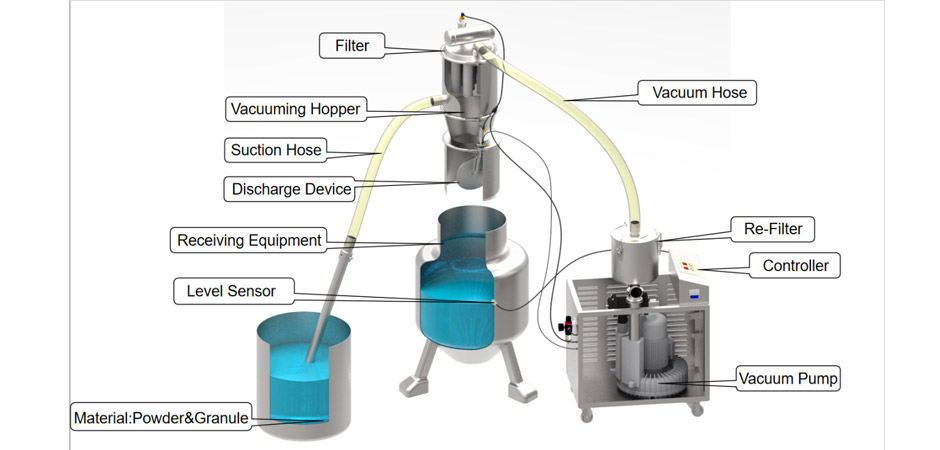

ZKS vacuum conveyor uses vacuum pump as the power source, when the vacuum pump works, the whole system generates negative pressure to form vacuum airflow, the powder materials along with air are sucked into vacuum hopper through the suction hose, the filter separates the air from the materials, when the material is filled with the vacuum hopper, the controller will automatically cut off the power supply, the vacuum pump stops working, the discharge door opens automatically, and the material falls into the hopper of the feeding equipment. At the same time, the compressed air automatically cleans the filter through the pulse back-blow valve. When the set time is reached or the material level sensor sends the feeding signal, the feeding machine will automatically repeat the previous working cycle.

| Eletric model | Power(kw) | Hopper diameter(mm) | Capacity(kg/h) |

| ZKS-1 | 1.5 | φ220 | 200 |

| ZKS-2 | 2.2 | φ220 | 500 |

| ZKS-3 | 3 | φ290 | 1000 |

| ZKS-4 | 5.5 | φ420 | 2000 |

| ZKS-5 | 5.5 | φ420 | 3000 |

| ZKS-6 | 7.5 | φ420 | 4000 |

| ZKS-7 | 7.5 | φ600 | 5000 |

| ZKS10-6-5 | 7.5 | φ600 | 6000 |

| ZKS-20-2 | 11 | φ600 | 8000 |

| Pneumatic model | Air consumption(l/min) | Hopper diameter(mm) | Capacity(kg/h) |

| QVC-1 | 180 | φ140 | 100 |

| QVC-2 | 360 | φ220 | 200 |

| QVC-3 | 720 | φ290 | 1000 |

| QVC-4 | 1440 | φ420 | 2000 |

| QVC-5 | 2880 | φ600 | 3500 |